Main Content

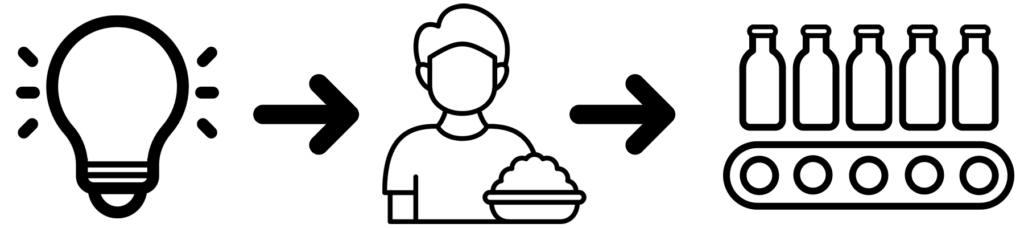

At the Food Innovation Center at Rutgers (FIC), we’ve helped hundreds of clients successfully build and grow their businesses. We pride ourselves on being supportive and knowledgeable mentors with many decades of collective industry experience. Our wide range of fee-based services can be customized based on the client’s needs, and support the product development process from concept to commercialization.

Business Ideation and Strategy

FIC can help by analyzing and providing guidance on the market / category, competition, consumers and trends that can help the client in developing the product concept for the best chance of success.

Examples of some of the services FIC provides:

- Category Assessment: Utilizing industry information along with Rutgers secondary research resources can provide a brief overview of the category and key drivers

- Competitive Assessment: FIC can help identify key competitors and assess the competition versus the client’s product concept on key product and packaging attributes, etc. to help identify key points of difference

- Sensory Competitive Assessment: The FIC internal team evaluates the clients product versus the key competitors on sensory attributes. The results from this evaluation help guide product development efforts.

Product Research and Development

FIC provides the basic steps to bring a food idea into commercial production. Each product development plan is customized to meet each client’s needs. The process typically includes:

- Review of concept with FIC team

- Review of the formula and process

- Basic analytical and bench top work to create an initial prototype with preliminary specifications

- Documentation of the product specifications

- Ingredient statement and theoretical Nutrition Facts panels can be developed using the Genesis program

Package

Package development is usually done in tandem with product development. FIC can provide guidance and suggested resources on packaging engineering, package performance testing, shelf life and environmental testing and package design and labeling.

Pilot Plant and Commercial Production

Scale Up and Commercialization

The scale up process takes a recipe or early prototype and turns it into a formulation that can be manufactured. This phase usually requires the move from a kitchen to a larger production venue (i.e., pilot plant / plant), where the business can continue to grow. FIC has FDA- and USDA-certified facilities and can provide the guidance to make sure the newly scaled product is commercially produced and ready for sale.

Broad Array of Product/Process Capabilities

- Refrigerated Foods Processing

- Refrigeration controlled facilities for fresh-cut produce, or value-added meat, poultry or seafood products

- Beverages and Hot Processing

- Processing equipment for Beverages, Soups, Sauces, Stews, Salsas, Jams and Jelly, Grilled and Roasted Vegetables, and Prepared Entrees

- Bottling line that allows for automated production specializing in Acidified, Hot Filled products

- Dry Processing

- Cold Assembly/Clean Room

- Packaging of perishable products in HEPA-filtered clean room

- Blast Chilling and Freezing

- Refrigerated, Frozen & Ambient Storage

International Soft Landings Program

The Food Innovation Center at Rutgers is leveraging its historical successes with supporting international businesses, its designation as the only InBIA-recognized Soft Landings program in the world, and New Jersey’s strategic location as the gateway to the US market and partnering with organizations to attract global food businesses to the Garden State.

FIC has successfully mentored several global businesses from Greece, Italy, India, Israel and many other countries.

Services and capabilities

- Help assess the viability of market entry into the US

- Help clients to understand the trends, consumers, logistics and regulations of the local market

- Provide access to resources on logistics, regulations, distribution and food safety to import products into US

- Business and technical mentors that can support global business from start to finish and provide guidance on a go to market strategy

- Partnership with several organizations that support global companies looking to establish a presence in New Jersey (i.e., Choose NJ, NJEDA, NJ Business Action Center, etc.)

Food Safety Certificate Courses

We offer a diverse array of food safety training and specialized services to meet the needs of the food industry, and we are happy to discuss how these can be successfully applied to your company. Please read all descriptions, locations and dates for classes carefully as they are non-refundable. If you are unable to attend a class after registering, you may transfer to another FIC-taught class at a later date.

Training and Specialized Services include:

- Good Manufacturing Practices (GMPs) with Personal Hygiene & Adverse Health Conditions

- Hazard Analysis and Critical Control Points (HACCP) [Not for Seafood or Juice]

- Preventive Controls for Human Food [PCHF]

- Preventive Controls for Animal Food [PCAF]

- Foreign Supplier Verification Program [FSVP]

- Implementing Safe Quality Foods Systems training [SQF]

- ServSafe Manager Certificate training class

- ServSafe Manager Certificate exam, proctoring only

Course Instructors

The primary Instructor for these courses is Mellonie O’Neill, Senior Manager of QA Compliance and Training at the Rutgers Food Innovation Center. Mellonie’s years working in the food processing industry provides her with real-life examples to supplement the standardized training materials presented in these classes.

In addition to her degree in Food & Nutrition Technology, Mellonie’s recent attainment of a master’s degree in Adult and Continuing Education with a concentration in Educational Technology equips her to teach classes in a virtual format to allow students to take these classes from any location with internet access.

All food safety courses taught at the FIC allow participants to earn a certificate of attendance from Rutgers University or the appropriate certificate from the International HACCP Alliance or the Association of Food & Drug Officials.

Food Safety Consulting

Don’t know where to start with your 3rd party audits or with your food safety programs? We can help! Our staff are industry veterans with decades of food manufacturing experience. We can work with you to personalize the consulting services for exactly what you need.

Our services available include:

- FSMA (Food Safety Modernization Act) gap audits for Preventive Controls for Human Foods (PCQI)

- Assisting with the creation of Food Safety Plans for any FDA regulated facility

- Assisting with the creation of HACCP Plans and/or facility specific employee training

- Conducting facility gap audits for GMP (Good Manufacturing Practices) compliance or to assist and prep for 3rd party audits

- Assisting food manufacturers with meeting U.S. regulatory requirements with food safety training (GMPs, Adverse Health & Personal Hygiene, etc.), audit readiness, food safety plans, facility conditions, and sanitation programs

- Assisting in setting up and/ or reviewing Environmental Monitoring Programs (EMPs)